Waterproof Wire to Wire and Wire to Board Connectors

- Wire to Wire and Wire to Board Connectors

- Waterproof Wire to Wire and Wire to Board Connectors

- Wire Connectors

- Waterproof Wire Connectors

- Double Latch Technology

Categories

- Card Edge Connectors

- RECTANGULAR CONNECTORS

- D-Sub Connectors

- Machined D-Sub Connectors

- Power Combo D-Sub Connectors

- Parallel Port D-Sub Connectors

- Waterproof D-Sub Connectors

- DB9 Connector

- DB15 Connector

- DB25 Connector

- Vertical PCB D-Sub Connector

- D-Sub Panel Cut-outs

- Cable Wire D-Sub Connector

- PCB D-Sub Connector

- Right-angle PCB D-Sub Connector

- Backshells or Hoods, and Caps for D-Sub Connectors

- D-Sub Connector Housings

- D-Sub Connector Contacts

- Modular & Magnetic Jacks

- USB Connectors

- HDMI Connectors

- INLINE CONNECTORS

- HEADER CONNECTORS

- Spring Loaded Connectors

- Waterproof Connectors

- Cable Assemblies

- Custom Connectors

Search Parts:

The EDAC E-Inline family of waterproof plug and socket connectors provides a reliable interconnect solution in harsh environments. Single or double latch insulator designs insure superior shock and vibration resistance. A variety of styles are available for different wire gauge applications. These utilize simple crimp and poke contacts. Optional contact plugs are available for use when all contact positions are not required. Additional contacts/wires can then be added in the field.

Waterproof Wire to Wire and Wire to Board Connectors Series

Series |

Description |

|---|---|

560 Series

|

IP67 | E-Seal | In-Line Waterproof Connectors | 2.50mm Pitch | Double Latch |

565 Series

|

IP67 | E-Seal | In-Line Waterproof Connectors | 2.50mm Pitch |

566 Series

|

IP67 | E-Seal | In-Line Waterproof Connectors | 2.00mm Pitch |

567 Series

|

IP52 | E-Seal | In-Line Waterproof Connectors | 5.00mm x 5.90mm Pitch |

568 Series

|

IP52 | E-Seal | In-Line Waterproof Connectors | Single Pin |

570 Series

|

IP67 | E-Seal | In-Line Waterproof Connectors | 5.80mm Pitch |

572 Series

|

IP67 | E-Seal | In-Line Waterproof Connectors | 5.80mm Pitch | Double Latch |

Accessories Series

|

E-Seal Waterproof Inline Connector Accessories |

What is a Waterproof Inline Connector Housing?

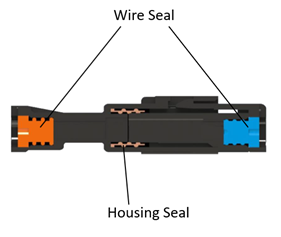

Waterproof Inline connector housing provides a protection to the waterproof inline connectors, both wire-to-wire and wire-to-board and achieve true crimp and pole solution. Internal polarization can prevent mis-mating and seals are preassembled into the housing such that external sealing is not required. 1 to 6, or 9 positions of inline connector with some single or double latch solutions are available. Also, waterproofing cap 565-200-100 for series 565 and 560, and 566-200-100 for series 566 can be provided to cover unused positions.

Section view of Wire-to-Wire waterproof housing assembly

Tools for EDAC Waterproof inline connectors

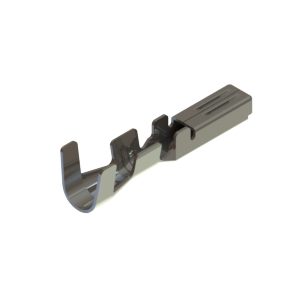

Since both pin and socket of the inline connector is crimp contact, both automatic and manual crimping tools are available. For automatic contact crimp machine tool (part number 516-280-700), it can crimp all 560, 565, 566, 567, 568, 570 and 572 series contacts by foot switch and easy access for all setting changes. It can be mounted to any bench surface and guards required for operator safety.

Automatic contact crimp machine tool 516-280-700

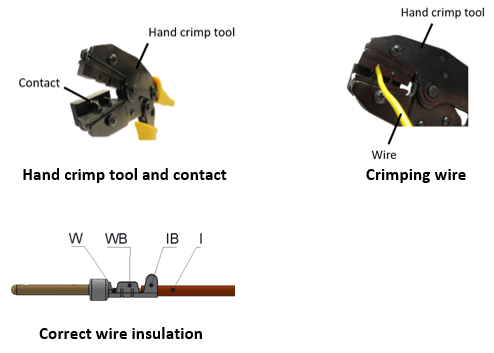

For hand crimp tools 565-280-201 for 560 and 565 series, 570-280-201 crimper for 567, 568, 570 and 572 series, and 566-280-201 crimper for 566 series are available to crimp the male and female contact with the wire before inserting into the inline connectors. Firstly, open the hand crimper and place the contact into locator slot. Then, partially close the crimper until the contact is held in place. Insert the wire into the contact and close the crimper until the ratchet releases. Make sure the wire insulation (I) is properly located on the insulation barrel (IB) of the contact and wire copper (W) on the wire barrel (WB) of the contact. The contact can be inserted into the connector by tweezer.

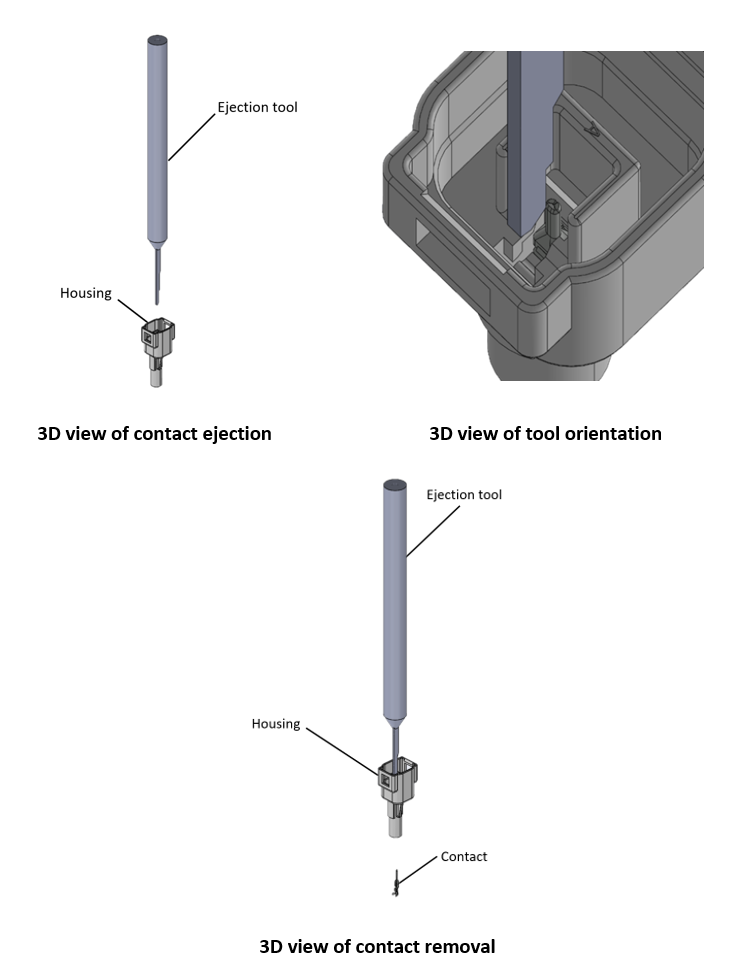

The ejection tool 570-280-300 for 567, 568, 570 and 572 series contacts, and 565-280-301 for 560 series contacts are available. The contact can be removed from the housing by inserting the ejection tool into the front of the housing in a correct orientation shown in the picture below, then keep pressing down. However, please note that the insertion of the contact is IRREVERSIBLE as this will damage the plastic slot in the housing, which fails to hold the contact.

We continually update and advance our products to ensure that our customers have access to the latest and best products available. Contact us for additional information.