DB25 Connector

- Machined D-Sub Connectors

- Power Combo D-Sub Connectors

- Parallel Port D-Sub Connectors

- Waterproof D-Sub Connectors

- DB9 Connector

- DB15 Connector

- DB25 Connector

- Vertical PCB D-Sub Connector

- D-Sub Panel Cut-outs

- Cable Wire D-Sub Connector

- PCB D-Sub Connector

- Right-angle PCB D-Sub Connector

- Backshells or Hoods, and Caps for D-Sub Connectors

- D-Sub Connector Housings

- D-Sub Connector Contacts

Categories

- Card Edge Connectors

- RECTANGULAR CONNECTORS

- D-Sub Connectors

- Machined D-Sub Connectors

- Power Combo D-Sub Connectors

- Parallel Port D-Sub Connectors

- Waterproof D-Sub Connectors

- DB9 Connector

- DB15 Connector

- DB25 Connector

- Vertical PCB D-Sub Connector

- D-Sub Panel Cut-outs

- Cable Wire D-Sub Connector

- PCB D-Sub Connector

- Right-angle PCB D-Sub Connector

- Backshells or Hoods, and Caps for D-Sub Connectors

- D-Sub Connector Housings

- D-Sub Connector Contacts

- Modular & Magnetic Jacks

- USB Connectors

- HDMI Connectors

- INLINE CONNECTORS

- HEADER CONNECTORS

- Spring Loaded Connectors

- Waterproof Connectors

- Cable Assemblies

- Custom Connectors

Search Parts:

A DB25 connector is an established parallel port connection in computers often referred to as a printer port. These 25-pin d-subs offer rugged connections of peripherals and have excellent shock and vibration resistance. Vertical or right-angle orientations combined with various mounting options make these d-subs and excellent choice in industrial applications.

DB25 CONNECTOR | EDAC

What is a db25 connector?

The DB25 connector is an analog socket, with 25 pins, from

the

D-Subminiatures (D-Sub) connector family. The prefix “D” represents the D-shape of the

connector shell. The DB25 connector is mainly used in serial and parallel

ports, allowing asynchronous data transmission according to the RS-232 standard

(RS-232C). Note that there are DB9-DB25 adapters that easily convert a DB9

socket to DB25 and vice versa.

DB25 ENGINEERING OPTION

There are three types of cable end D-sub connectors. They are differentiated by the method used to attach the wires to the contacts: soldering, insulation displacement or crimping.

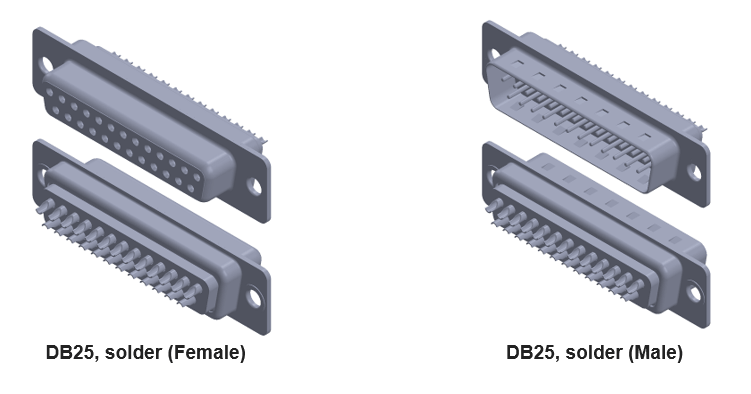

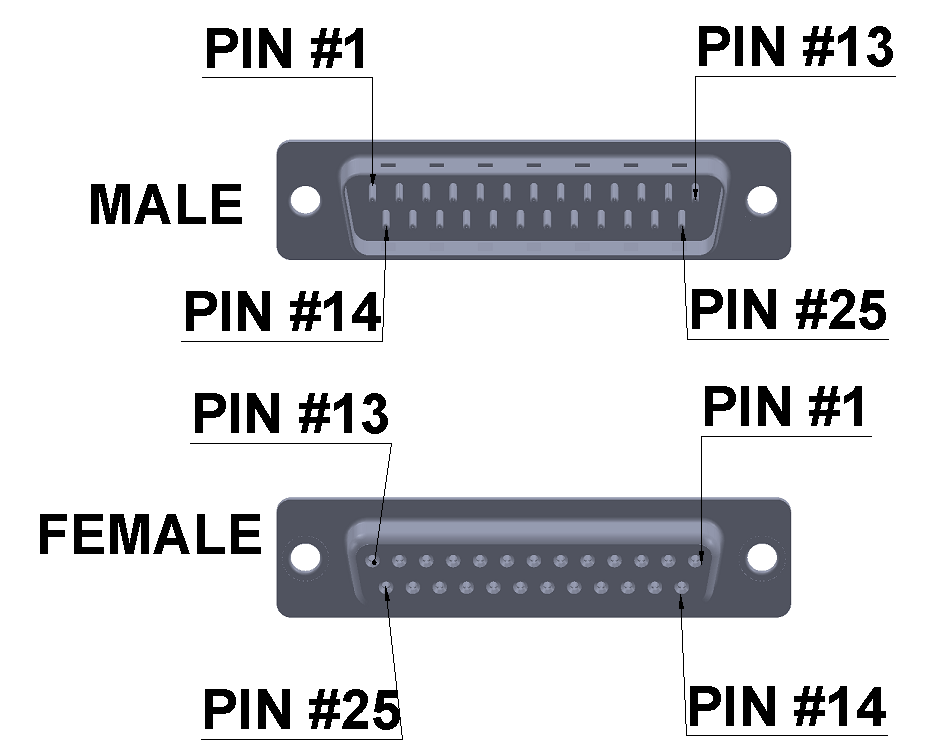

1. DB25 DSUB CONNECTOR WITH SOLDER CONTACTS

The solder contacts have a cavity into which the stripped and tinned wire is inserted and then soldered.

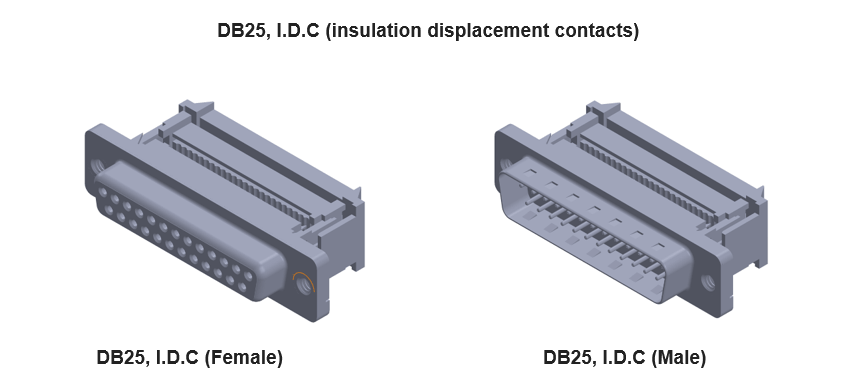

2. DB25 D-Subminiature Connector with Insulation Displacement Contacts (IDC)

The insulation displacement contacts (I.D.C.) are designed for automated assembly. A flat cable is pressed against the contacts, the rear of which is fork-shaped, which then pierce the insulation of all the wires simultaneously.

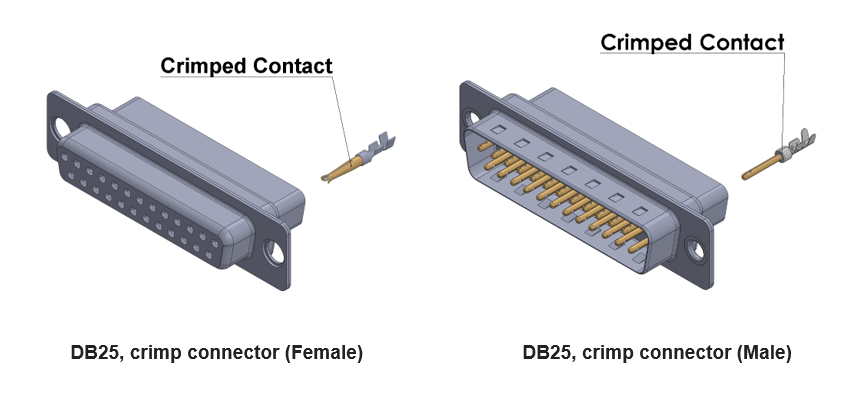

3. DB25 DSUB CONNECTOR WITH CRIMPED CONTACTS

The crimp contacts are wired by inserting a stripped end of wire into a cavity at the back of the contact. The cavity is then crimped using a crimping tool. The contact is then inserted into the connector. Pins can be removed later with a tool inserted into the back of the connector. This "rear disconnect" is useful when the pins on the device are damaged.

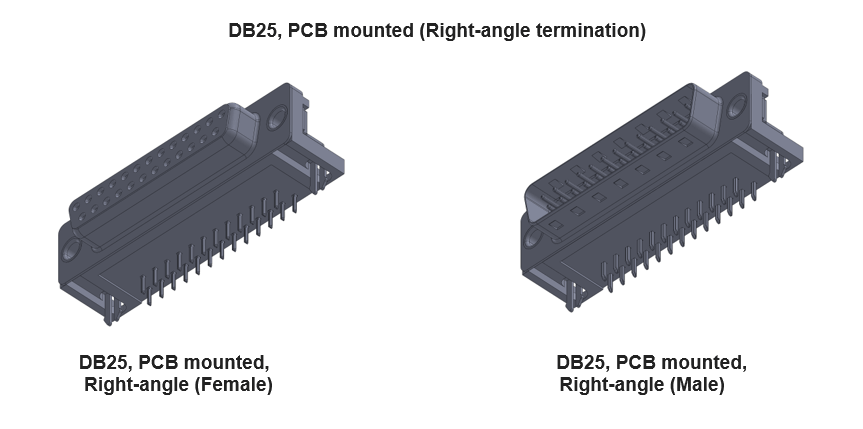

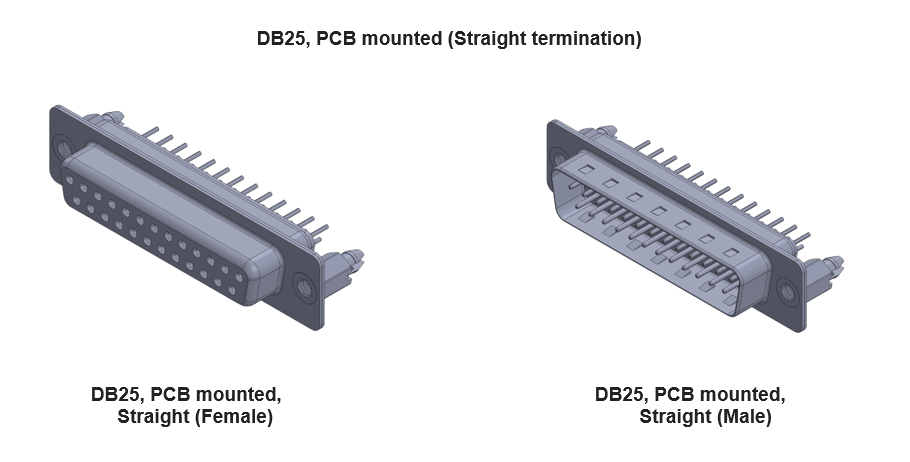

pcb mOUNTED dsUB DB25 cONNECTOR

There are also two types of PCB mounted connectors, straight or right-angle termination styles. This type of connector has built-in solder tails for easy mounting on a PCB.

RIGHT-ANGLE TERMINATION -

Straight Termination -

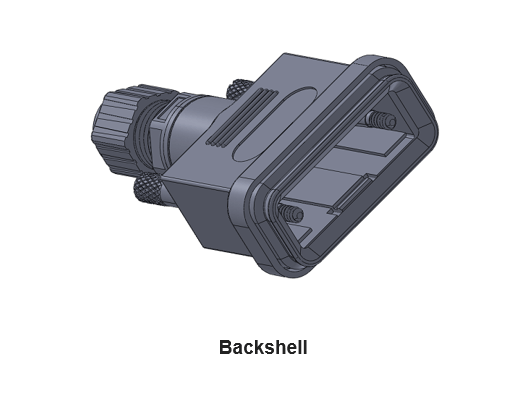

DB25 D-SUB CONNECTOR BACKSHELLS

D-Sub connector backshells enclose the junction between the conductors in a cable and the contacts in the connector assembly. These are available in plastic for standard applications, or metal for industrial applications.

Other commonly known D-subs are DB9 connectors and DB15 connectors.

Contact us at EDAC for more information! Experience makes the difference.