DB15 Connector

- Machined D-Sub Connectors

- Power Combo D-Sub Connectors

- Parallel Port D-Sub Connectors

- Waterproof D-Sub Connectors

- DB9 Connector

- DB15 Connector

- DB25 Connector

- Vertical PCB D-Sub Connector

- D-Sub Panel Cut-outs

- Cable Wire D-Sub Connector

- PCB D-Sub Connector

- Right-angle PCB D-Sub Connector

- Backshells or Hoods, and Caps for D-Sub Connectors

- D-Sub Connector Housings

- D-Sub Connector Contacts

Categories

- Card Edge Connectors

- RECTANGULAR CONNECTORS

- D-Sub Connectors

- Machined D-Sub Connectors

- Power Combo D-Sub Connectors

- Parallel Port D-Sub Connectors

- Waterproof D-Sub Connectors

- DB9 Connector

- DB15 Connector

- DB25 Connector

- Vertical PCB D-Sub Connector

- D-Sub Panel Cut-outs

- Cable Wire D-Sub Connector

- PCB D-Sub Connector

- Right-angle PCB D-Sub Connector

- Backshells or Hoods, and Caps for D-Sub Connectors

- D-Sub Connector Housings

- D-Sub Connector Contacts

- Modular & Magnetic Jacks

- USB Connectors

- HDMI Connectors

- INLINE CONNECTORS

- HEADER CONNECTORS

- Spring Loaded Connectors

- Waterproof Connectors

- Cable Assemblies

- Custom Connectors

Search Parts:

DB15 connectors are most commonly known as VGA d-subs and provide data flow to monitors, but it can also be used in many other applications; particularly in industrial and medical segments. The D-shaped shell provides automatic polarization as it only fits one way. EDAC offers a slim VGA with vertical pins but side cable entry that saves up to 70% board space!

DB15 Connector | edac

What is a db15 connector?

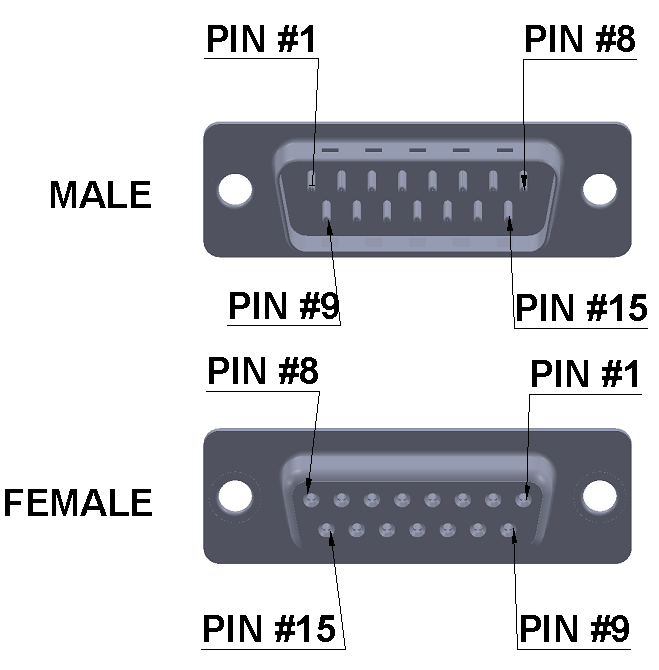

The DB15 connector is an analog socket, with 15 pins, from

the

D-Subminiatures (D-Sub) connector family. The prefix “D” represents the D-shape of the connector

shell. The DB15 connector is mainly used in serial and parallel

ports, allowing asynchronous data transmission according to the RS-232 standard

(RS-232C).

DB15 Engineering Options

There are three types of cable end DB15 D-sub connectors. They are differentiated by the method used to attach the wires to the contacts: soldering, insulation displacement or crimping.

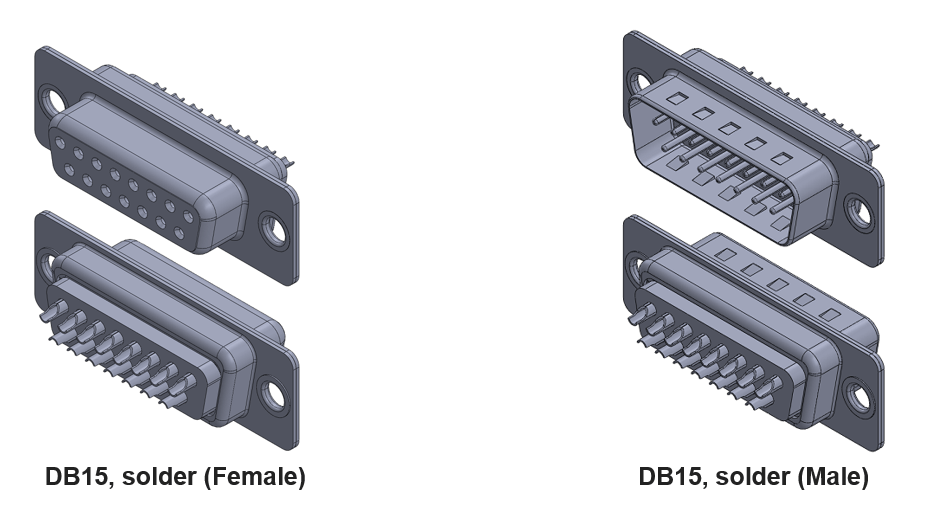

1. DB15 DSUB connector with SOLDER CONTACTS

The solder contacts have a cavity into which the stripped and tinned wire is inserted and then soldered.

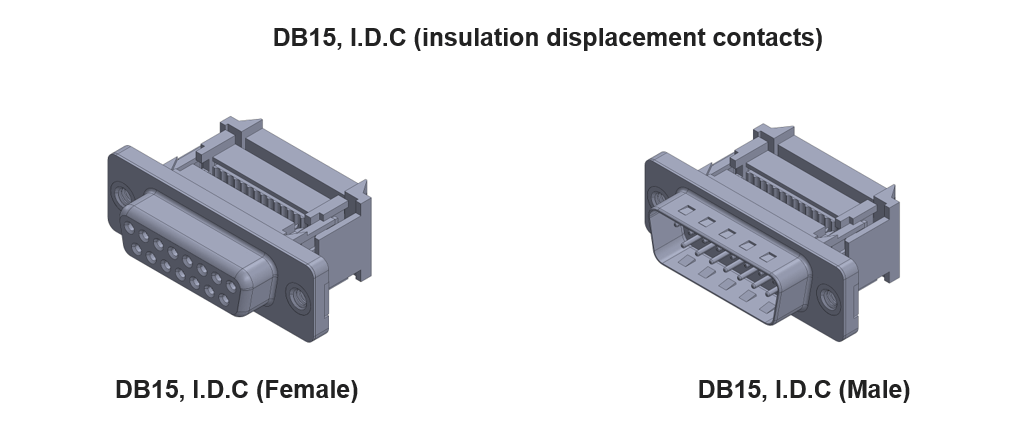

2. DB-15 DSUB Connector with INSULATION DISPLACEMENT CONTACTS (idc or i.d.c)

The insulation displacement contacts (I.D.C.) are designed for automated assembly. A flat cable is pressed against the contacts, the rear of which is fork-shaped, which then pierce the insulation of all the wires simultaneously.

3. DB15 DSUB connector with CRIMPED CONTACTS

The crimp contacts are wired by inserting a stripped end of wire into a cavity at the back of the contact. The cavity is then crimped using a crimping tool. The contact is then inserted into the connector. Pins can be removed later with a tool inserted into the back of the connector. This "rear disconnect" is useful when the pins on the device are damaged.

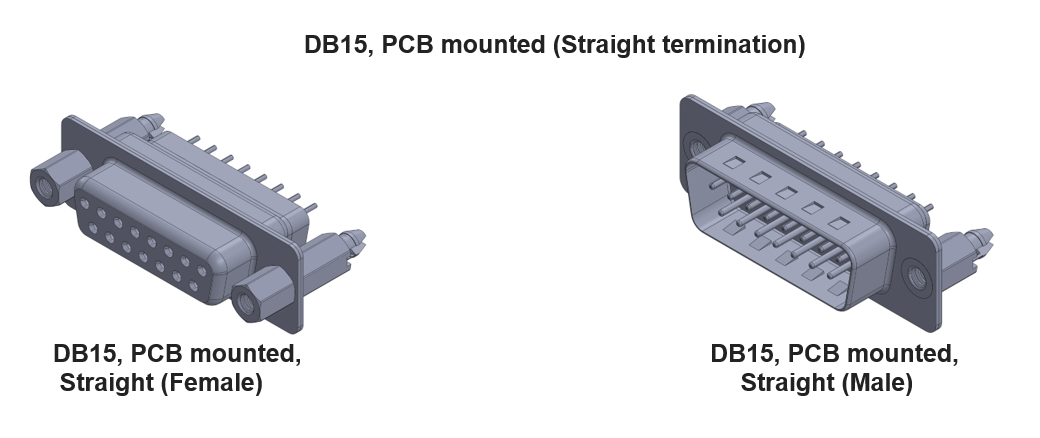

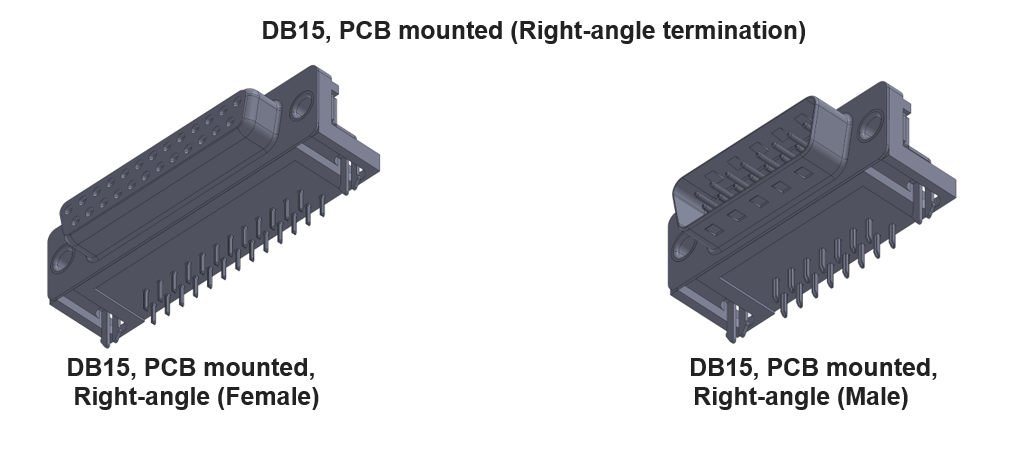

Db15 DSUB CONNECTOR TERMINATION STYLES - STRAIGHT AND RIGHT-ANGLE

There are also two types of PCB mounted connectors, straight or right-angle termination styles. This type of connector has built-in solder tails for easy mounting on a PCB.

STRAIGHT termination -

Right-angle termination -

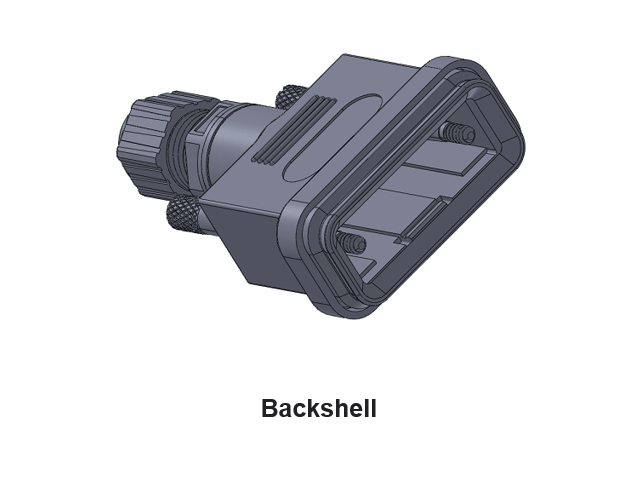

DB15 D-SUB connector BACKSHELLS

D-Sub connector backshells enclose the junction between the conductors in a cable and the contacts in the connector assembly. These are available in plastic for standard applications, or metal for industrial applications.

Contact us at EDAC for more information! Experience makes the difference.