The most common connectors used in transportation applications are Card-Edge, Rectangular, USB, and HDMI. Card Edge connectors continue to be used in the transportation market. In conformance with “MIL-STD-202, Method 204”, these are utilized in backplanes with PC boards in traffic control equipment to provide various functions such as traffic lights, security camera feeds, etc. Rectangular rack & panel connectors are used when high shock and vibration resistance is required such as in train rail signaling equipment. USB connectors are commonly used in traffic camera applications as a power source providing data feedback to the control monitor. HDMI connectors transfer video signals from a traffic camera back to the control monitor displaying traffic activity.

The most common connectors used in transportation applications are Card-Edge, Rectangular, USB, and HDMI. Card Edge connectors continue to be used in the transportation market. In conformance with “MIL-STD-202, Method 204”, these are utilized in backplanes with PC boards in traffic control equipment to provide various functions such as traffic lights, security camera feeds, etc. Rectangular rack & panel connectors are used when high shock and vibration resistance is required such as in train rail signaling equipment. USB connectors are commonly used in traffic camera applications as a power source providing data feedback to the control monitor. HDMI connectors transfer video signals from a traffic camera back to the control monitor displaying traffic activity.

A Look at Connectors and Their Engineering Considerations for Transportation Applications

Introduction

The transportation industry covers quite a broad range of applications from mass transit and railway to marine and off-road equipment. Within these applications, there is a vast array of connector arrangements required for the subsystems that are used for these various modes of transport as well as the systems used to monitor and control them.

Traffic control systems for automobile and railway applications, for instance, will utilize large cabinets with racks of mounted equipment within them to monitor pedestrian, vehicle, or railway traffic. These systems may also supplement their monitoring with the use of cameras and additional wireless equipment in order to remotely transmit and receive critical information. Heavy equipment and off-road vehicles will often use large installations of wire harnesses in order to transmit and distribute signal/power to the vehicle. All of these applications are subject to both environmental and mechanical strain which require their interconnects to maintain a high integrity connection despite these various stressors, calling for a ruggedized connector housing with an innovative construction and unique mating structures.

In this article, we will discuss some of the connectors used in these applications and the engineering considerations around their selection.

Trends in transportation

Transportation on the whole is experiencing a mass shift toward electrification as battery technology, power-dense switching technologies, and charging infrastructure all improve. Railway applications now span from electric trams, trolleys, and city subway systems to high-speed electric trains that use overhead power lines, or catenary systems, to supply electricity to the train via an overhead pantograph. The traditional automotive internal combustion engine (ICE) is now being replaced with energy storage systems (ESS) that supply the electric powertrain with energy for mobility. Even larger, heavy-duty machinery such as construction, mining, agricultural, and off-road utility equipment are experiencing the trend toward electrification with hybrid ICE/battery-powered systems to improve both efficiency and sustainability credentials.

At the same time, there is a focus on ensuring these power-dense systems can be contained in smaller, more aesthetically appealing packages. This can be seen with the shift to gallium nitride (GaN)- and silicon carbide (SiC)-powered devices within the transportation industry. These wide bandgap semiconductors enable charging circuits and power supply topologies (e.g., OBCs, DC fast-chargers, power supply, DC/AC catenary converters, auxiliary power supplies) to have faster switching speeds which, in turn, allows the circuit to achieve a much higher efficiency with simpler designs that include fewer power devices/gate drivers and peripheral components (e.g., passives, magnetics). This characteristic, in combination with the relatively high thermal conductivity of both SiC and GaN (compared to Si), also simplifies thermal management considerations ― oftentimes shrinking the overall solution size.

Design constraints within the transportation industry: An overview

The goals of improving efficiency and lowering emissions cannot be met without the inherent stress that comes with high-speed mobility in transportation-based applications. All of these use cases will encounter vibrations due to turbulence, high winds, and other general factors that resist forward motion. There are also many cases where mechanical shock, or a sudden abrupt impact (e.g., collision, hard braking) can deform the equipment and its connections. Both transportation control and equipment endure the unpredictable environmental strain that comes from an unsheltered environment. This is often mainly in the form of humidity, salty (corrosive) atmospheres, and temperature extremes. In other cases, namely heavy-duty equipment, there are other contaminants that could potentially disrupt sensitive internal circuits and connections such as exposure to hydraulic fluid or engine oil.

There are added regulatory considerations: ICs used within the automotive industry are often AEC-Q100- or AEC-Q200-qualified with various ISO 60512 automotive testing. The SAE J2030 standard includes environmental test requirements and acceptance criteria for heavy-duty connectors in heavy-duty applications such as off-highway machinery. Electrical equipment in railway systems has its own set of standards as well, such as IEC 60077 and EN 50155 which address temperature, humidity, shock, vibration, and power supply variations.

The power supplies within modern transportation systems exhibit increasingly higher switching frequencies. This allows for better efficiency but also creates the risk of generating unwanted noise that can interfere with nearby circuits. For this reason (and many more) EMC constraints are placed upon these systems with limits on both radiated and conducted emissions. Some of these standards are specific to automotive use cases (e.g., ISO 11451, EN 50498) and railway applications (e.g, IEC 62239, EN 50121), while others are more general (e.g., CISPR 25).

Connectors that are housed within these systems must be able to fit within these small form factors and withstand the harsh conditions without losing the integrity of the connection. A range of connectors and cable assemblies are required in order to satisfy the variety of power, signal, and data connections within these systems; however, they often must be ruggedized.

Overall, transportation-based applications face a number of challenges in terms of reliability and performance. However, by carefully selecting components and designing systems to withstand the harsh environment, it is possible to build reliable and efficient transportation systems.

Connectors in traffic control equipment

Traffic control equipment consists of a controller, detector card, load switches and flasher, monitor, and power supply. Figure 1 shows a typical traffic cabinet and a block diagram of its respective hardware/equipment.

Figure 1: Traffic signal cabinet with a basic diagram of its hardware [1]. Image source: ALDOT

A traffic signal controller (e.g., an eight-phase NEMA traffic signal controller) receives data from various sources, such as vehicle detectors and pedestrian pushbuttons, and uses algorithms to determine the appropriate right-of-way assignments with predetermined intervals, or phases. The controller then outputs this information to displays that maintenance personnel can use to troubleshoot and monitor the system. Detector cards are used with sensing apparatus, such as inductive loops or video-detection systems, to detect vehicles by measuring the change in the loop’s inductance caused by the passing vehicle. This information is passed along to the controller for further processing. Load switches control the power supplied to traffic lights, and in the event of a traffic signal failure, the flasher lights activate the “flashing mode” at the intersection. A traffic signal monitor (e.g., a NEMA MMU) works independently from the controller to ensure intersection safety from fault conditions (e.g., invalid signal voltage levels, burnt lamps, conflicting green lights, incorrect timing).

Many of these systems have the additional capability of monitoring intersections with high-resolution USB cameras to provide real-time sights with a wide field-of-view (FOV). This way, your license plate is captured the instant you realized that maybe you should have stopped at the yellow light. In these use cases, USB is the interface used to transfer both power and signal data to and from the control monitor. HDMI connectors will transfer these video signals from a traffic camera back to the control monitor that is displaying traffic activity.

As the image shows, a variety of connectors are used to provide data and power to and from the equipment in the cabinet. These connectors include:

- Rectangular/rack and panel connectors to connect between different components mounted within the cabinet

- Multi-pin circular connectors for the controller, detectors, and conflict monitor

- Ethernet and fiber-optic cables for connecting to modems

- Power cables for the cabinet's internal equipment

- Card edge connectors for connecting detector cards

- HDMI cables for connecting video signals from traffic cameras to displays

- USB cables for power and data connection from traffic cameras

The requirements of connectors used in these traffic control systems

Connectors and cable assemblies in traffic signal systems are mounted in cabinets that are exposed to the elements, so they must be able to withstand harsh environmental conditions. Wind gusts in bad weather can cause the cabinet (and its equipment) to shake, as well as the connections between them. The cabinet must protect sensitive circuitry with temperature/humidity control via an internal HVAC system or thermostatic heaters and fans. Despite this built-in temperature/humidity protection, the connectors must still be able to withstand any temperature fluctuations due to the cabinet's relatively exposed location. Typically, traffic control cabinets utilize either a NEMA architecture or a type 170/2070 that are rack-mounted based upon the type of controller being used in the application. In these use cases, rectangular rack and panel connectors may be required in order to connect to internal equipment.

Detector cards can handle multiple channels (multiple loops per detector) as well as various modes, these are typically circuit cards mounted in a card rack via a PCB card edge connector (Figure 2).

Figure 2: Multi-channel card rack with vehicle loop detectors. Image source: ALDOT

The restrictions on these connectors will vary based upon state and local regulations. For instance, the California and New York traffic controller system hardware in the late ‘70s required all connectors to be keyed to prevent accidental insertion of the wrong connector, and for card edge connectors to have bifurcated gold-plated contacts with very specific voltage and current ratings [3]. Naturally, this has changed over the past few decades; however, card edge connectors come in a variety of contact pitches, contact terminations, plating thicknesses, and mounting styles that can be optimized for the application. EDAC offers nearly 500,000 card edge connectors. Their metal-to-metal card edge connector line incorporates a fork-like design with four mating surfaces that provide a gas-tight connector with high shock and vibration resistance (Figure 3).

Figure 3: The EDAC two-piece, metal-to-metal, high-reliability connectors use hermaphroditic contacts with four mating surfaces for a ruggedized, gas-tight connection.

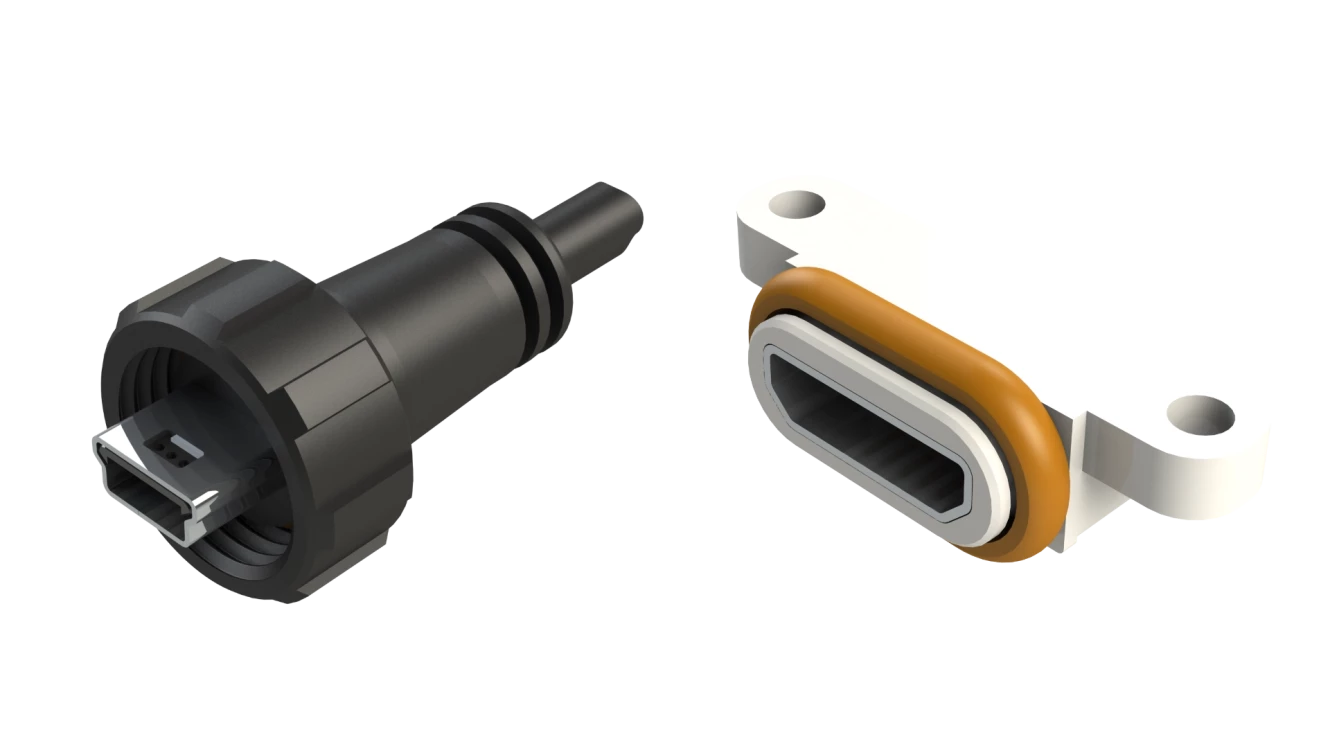

EDAC’s waterproof USB connectors ensure the connection to traffic cameras is not disrupted by corrosion or moisture ingress. As shown in Figure 4, these connectors use a quarter-turn twist-and-lock bayonet-style system for a secure connection despite vibration. Also available are waterproof board-mount connectors that utilize a full epoxy sealing of the contacts and use an O-ring seal to the panel.

Figure 4: EDAC’s 690W series of bayonet-mated waterproof USB Type-A connectors (left), and board-mount USB connectors (right).

Connectors used in railway signaling equipment

The European Train Control System (ETCS), in many ways, runs parallel to our previous example of a traffic control cabinet. This standard was intended to harmonize all of the disjointed national railway systems scattered throughout Europe. Composed of either onboard or trackside equipment, the ETCS systems communicate in order to maintain smooth railway operations. In-cab equipment can supervise train movements and calculate the maximum safe speed and braking curve based on the type of train, track conditions, and other factors. The trackside equipment consists of Balise (Eurobalise) or radio block centers (RBCs). The passive balises are installed on the track to store infrastructure-based data (e.g., speed, limits, gradients). The train antenna or balise transmission module (BTM) will receive this data when passing over it. RBCs are active devices that communicate with the in-cab equipment via GSM-R, a specialized network for railway operations [3]. An image of some of the subsystems used in ETCS is shown in Figure 5.

Figure 5: Some of the equipment found in ETCS highlighting the connectors and potential mechanical and environmental issues. Image source: European Commission

Some of the common connectors found in these applications are:

- Rectangular/rack and panel connectors for connection between racks and equipment

- D-subminiature connectors for data and signal transmission

- Circular connectors for a ruggedized data and signal connection to and from sensors or communication equipment

- HDMI Connectors for connecting signals for DMIs and in-cab displays

The requirements of connectors used in railway equipment

Similar to conventional traffic signaling systems, railway communications must be robust. These applications are particularly susceptible to unmating — intermittent signals due to faulty connections from vibrations or mechanical shock. This is a major factor to consider when choosing connectors for railway applications. Connections can also potentially be exposed to the elements, calling for a degree of water or ingress protection.

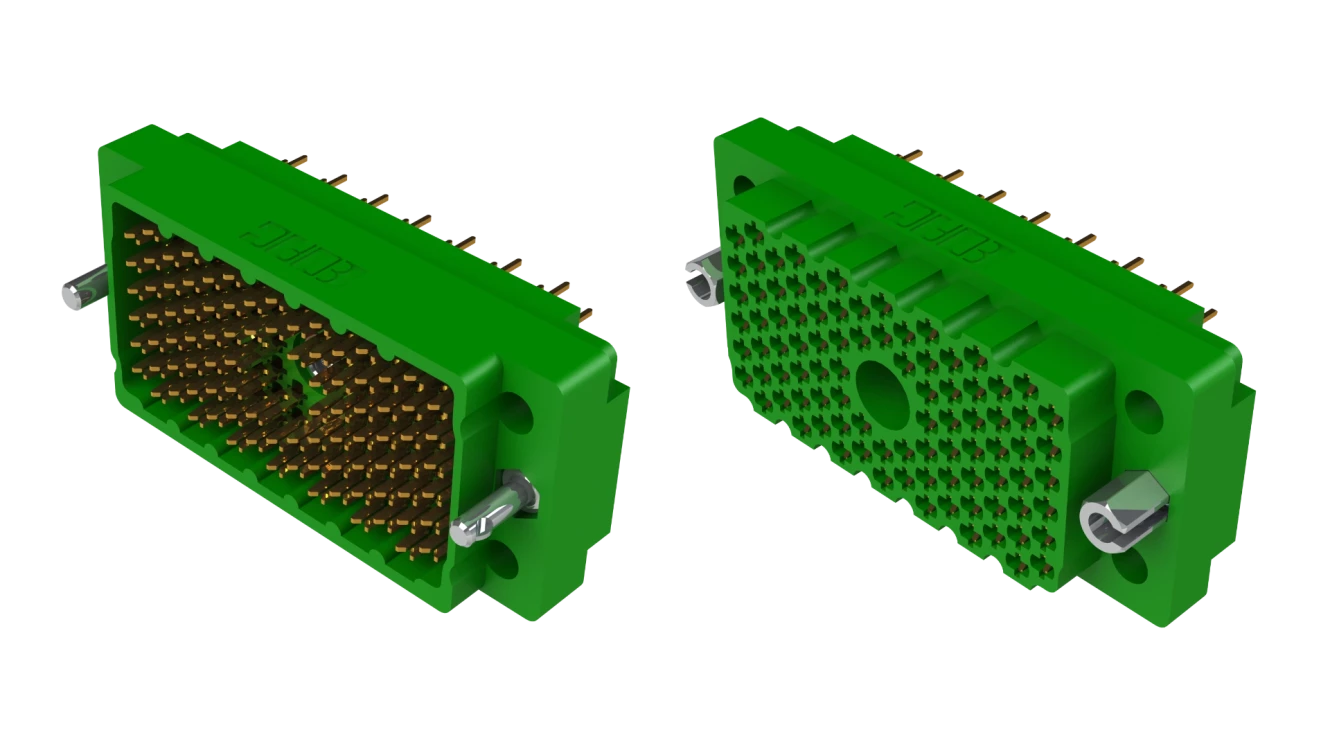

EDAC’s rectangular connectors offer a highly reliable connection with body sizes ranging from 14 to 120 contact positions. The connectors have an optional metal cover/backshell that provides dust, debris, and EMI protection as well as strain relief. This connector also features a hermaphroditic contact design to provide a gas-tight connection with shock and vibration resistance (Figure 6). MIL-C-28731 rectangular connectors are available through EDAC to provide another level of signal continuity and integrity despite shock and vibration.

Figure 6: An image of EDAC’s rectangular plug (left) and receptacle (right) with hermaphroditic contacts. The contacts align male and female insulators at 90 degrees to one another such that they provide four points of contact when mated.

EDAC offers waterproof D-sub connectors that are IP67-rated as per IEC 60529 (Figure 7). These connectors are epoxy-sealed, achieving zero ingress, no wicking up leads, and a smooth, molded finish with no air bubbles. This can be combined with a solid O-ring seal to the panel for a watertight connection.

Figure 7: EDAC D-sub connectors use an epoxy-sealing process that seals the back of the connector rather than individual pins for a watertight connection.

Connectors used in off-road vehicles

There are a great variety of electrical subsystems in heavy-duty machinery such as construction (e.g., excavator, backhoe, dump truck) and agricultural (e.g., combine harvester, tractor) equipment. Due to their confined space and distribution of electrical systems (e.g., ECM, ECU, TCM, lighting, HVAC, safety, infotainment, navigation, auxiliary systems), wiring harnesses are required. Established in the early ‘80s, the controller area network (CAN) protocol has been relied upon for a high-integrity connection between in-vehicle sensors, actuators, control modules, and other relevant systems within a vehicle. Figure 8 shows an engine control unit (ECU) mounted to a diesel Scania engine for heavy-duty equipment. The ECU communicates with relevant electrical subsystems/nodes using the CAN protocol. (Naturally, this causes the ambient temperature of the ECU to be high.)

Figure 8: An ECU mounted to a Scania diesel engine using CAN to communicate with various nodes within the vehicle. Image source: [4]

The connectors used in these applications can include:

- Sealed wire-to-wire and wire-to-board connectors in wiring harnesses

- Waterproof USB, HDMI, and D-sub connectors to connect to various human-machine interfaces (HMIs), control systems, and auxiliary charging systems within the cab

The requirements of connectors used in off-road equipment

Similar to railway applications, off-road equipment will also be exposed to extensive vibration and possibly more mechanical shock due to the nature of the work accomplished with these vehicles. The connectors will also experience intense temperature fluctuations being exposed to the outdoors for prolonged periods of time and will also experience heat being housed in heavy equipment that would likely utilize an ICE. However, the most considerable damage will likely be caused by moisture ingress and the potential exposure to chemicals such as hydraulic fluid, engine oil, etc.

The EDAC inline connectors include waterproof plugs and sockets for IP52- and IP67-grade protections. A double-latch system ensures a solid connection despite vibration and mechanical shock. The series has the flexibility of offering a variety of styles for different wire gauges, and simple crimp and poke contacts allow for a rapid setup and installation.

As shown in Figure 9, EDAC also offers custom wire harnesses and cable assemblies for data and signal processing as well as breakout cables for multiple terminations. Multiple connectors are available from EDAC’s stock (e.g., Mini USB, Mini DIN, RJ45, RJ11, inline). The vast range of connectors offered by EDAC ensures that virtually any cable manufactured can be used with an EDAC connector.

Figure 9: EDAC custom cable assembly with waterproof inline connectors.

Conclusion

The transportation industry hosts numerous types of connectors and cable assemblies, most of which must be able to withstand the environmental, mechanical, and electrical strain the equipment inevitably undergoes. EDAC offers a vast range of connectors supporting many subsystems found within these applications. These connectors are ruggedized to withstand dust/moisture ingress and are vibration and shock resistant.

Connect with us… Experience makes the difference.

RESOURCES

Transportation Application Web Page

References

- Alabama Department of Transportation. "Traffic Signal Design Manual." Alabama Department of Transportation, 2014, https://www.dot.state.al.us/publications/Design/pdf/TrafficDesign/TrafficSignalManual.pdf.

- The California/New York Type 170 Traffic Signal Controller System: Hardware Specification. U.S. Federal Highway Administration, 1978.

- European Commission. "Subsystems and constituents of ERTMS." Mobility and Transport, European Commission, https://transport.ec.europa.eu/transport-modes/rail/ertms/how-does-it-work/subsystems-and-constituents-ertms_en.

- Natale, Alberto Sangiovanni-Vincentelli, and Claudio Pinello. "Vehicle Applications of Controller Area Network." Handbook of Networked and Embedded Control Systems, doi:10.1007/0-8176-4404-0_32.