Waterproof D-Sub Connectors

- Machined D-Sub Connectors

- Power Combo D-Sub Connectors

- Parallel Port D-Sub Connectors

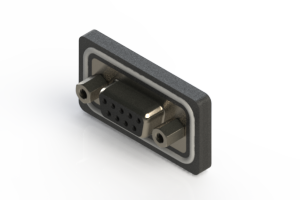

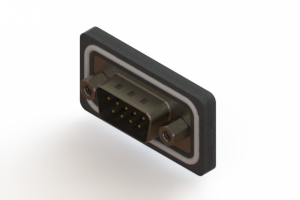

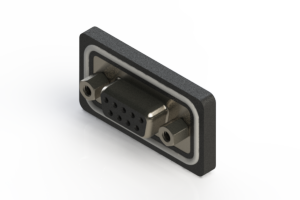

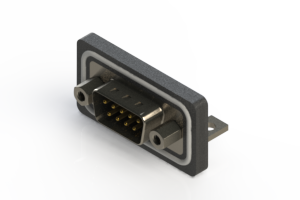

- Waterproof D-Sub Connectors

- DB9 Connector

- DB15 Connector

- DB25 Connector

- Vertical PCB D-Sub Connector

- D-Sub Panel Cut-outs

- Cable Wire D-Sub Connector

- PCB D-Sub Connector

- Right-angle PCB D-Sub Connector

- Backshells or Hoods, and Caps for D-Sub Connectors

- D-Sub Connector Housings

- D-Sub Connector Contacts

Categories

- Card Edge Connectors

- RECTANGULAR CONNECTORS

- D-Sub Connectors

- Machined D-Sub Connectors

- Power Combo D-Sub Connectors

- Parallel Port D-Sub Connectors

- Waterproof D-Sub Connectors

- DB9 Connector

- DB15 Connector

- DB25 Connector

- Vertical PCB D-Sub Connector

- D-Sub Panel Cut-outs

- Cable Wire D-Sub Connector

- PCB D-Sub Connector

- Right-angle PCB D-Sub Connector

- Backshells or Hoods, and Caps for D-Sub Connectors

- D-Sub Connector Housings

- D-Sub Connector Contacts

- Modular & Magnetic Jacks

- USB Connectors

- HDMI Connectors

- INLINE CONNECTORS

- HEADER CONNECTORS

- Spring Loaded Connectors

- Waterproof Connectors

- Cable Assemblies

- Custom Connectors

Search Parts:

The EDAC D-Seal series of IP67 rated waterproof D-Subminiature connectors are available in both standard and high density packages. Plug & receptacles in 9, 15, 25, 26 and 44 pin versions are available as well as high power combo configurations. Vertical and right angle footprints, with a variety of termination styles, contact plating thicknesses, and mounting options are available. A solid performer in ruggedized applications and harsh environments.

Waterproof D-Sub Connectors Series

Series |

Description |

|---|---|

627W Series

|

D-Sub Connectors | Waterproof | 0.109" (2.77mm) Contact Spacing x 0.112" (2.82mm) Row Spacing | Vertical | Plug |

628W Series

|

D-Sub Connectors | Waterproof | .109"(2.77mm) Contact Spacing x .112"(2.82mm) Row Spacing | Vertical | Receptacle |

629W Series

|

D-Sub Connectors | Waterproof | .109"(2.77mm) Contact Spacing x .112"(2.82mm) Row Spacing | Right Angle | Plug |

630W Series

|

D-Sub Connectors | Waterproof | .109"(2.77mm) Contact Spacing x .112"(2.82mm) Row Spacing | Right Angle | Receptacle |

633W Series

|

D-Sub Connectors | Waterproof | High Density | 0.090" (2.29mm) Contact Spacing x 0.078" (1.98mm) Row Spacing | Right Angle | Plug |

634W Series

|

D-Sub Connectors | Waterproof | High Density | 0.090" (2.29mm) Contact Spacing x 0.078" (1.98mm) Row Spacing | Right Angle | Receptacle |

637W Series

|

D-Sub Connectors | Waterproof | High Density | .090" (2.29mm) Contact Spacing x .078" (1.98mm) Row Spacing | Vertical | Plug |

638W Series

|

D-Sub Connectors | Waterproof | High Density | .090" (2.29mm) Contact Spacing x .078" (1.98mm) Row Spacing | Vertical | Receptacle |

waterproof D-sub connector

Waterproof D-sub connectors have all the same features of the standard D-sub, but are sealed with epoxy and contain a silicon O-ring to meet the waterproof protection rating IP67.

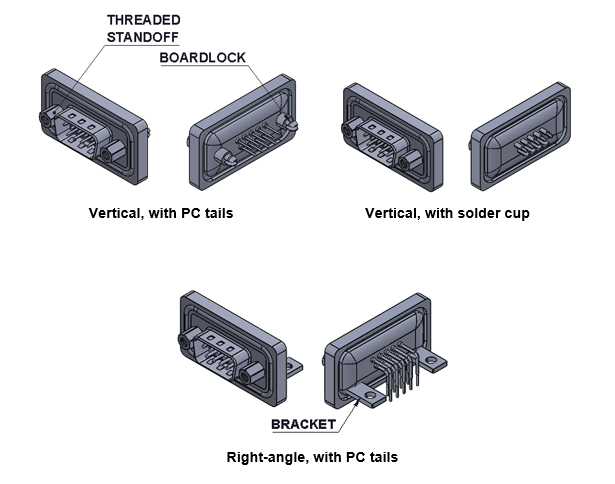

Engineering options

Waterproof D-sub connectors are available in vertical or right-angle orientations. Two contact termination options are available: PC tail and solder cup. Mounting options for panel mount or connector mating include threaded standoffs with or without boardlocks, and can be supplied with a mounting bracket for right angle PCB orientation.

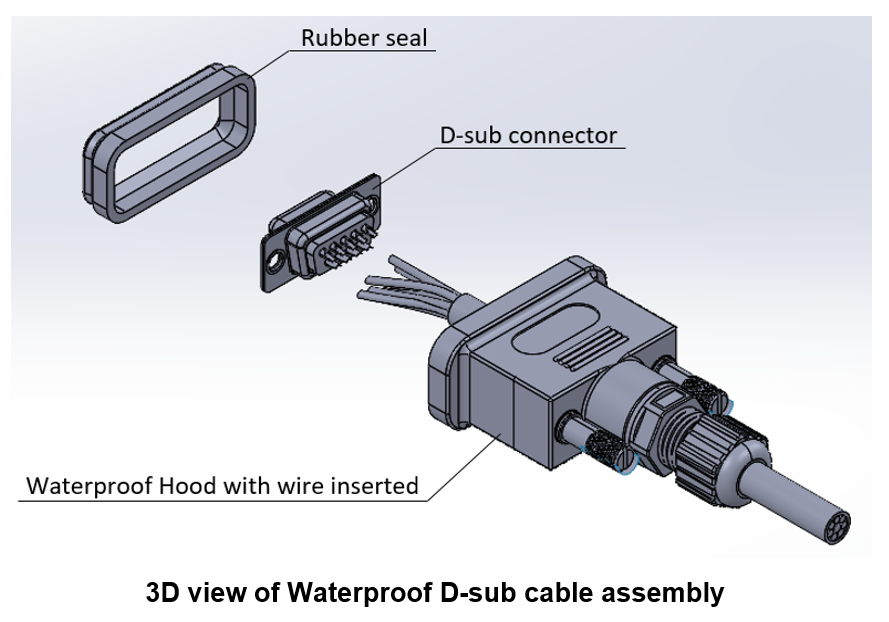

Cable or wired d-sub connector options

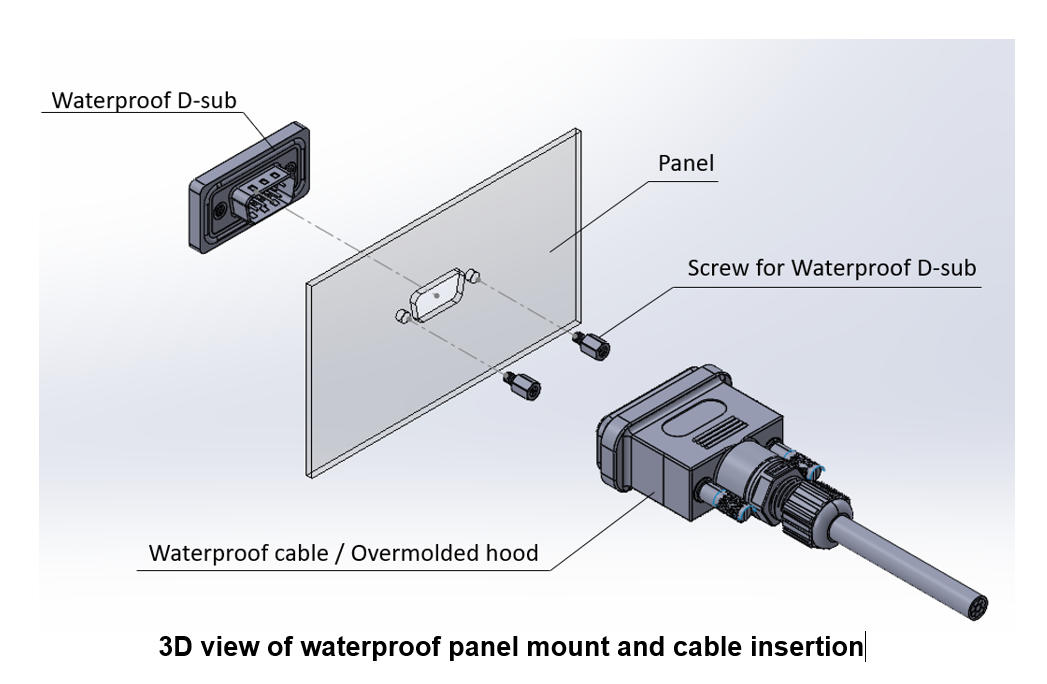

The D-sub connector can be waterproofed by inserting the connector into the waterproof hood. Over molded waterproof hoods or back shells are available with the D-sub and wire already pre-installed to the waterproof hood. A separate Waterproof hood or back shell is also available to manually assemble your own waterproof D-sub cable. First, take out the rubber seal from the hood and insert the wire from the back of the hood. Then, solder the wire to the solder cap on the D-sub connector, which the connector will be fixed in the hood after pushing into it firmly. Finally, tighten the cable screw on the hood and put the rubber seal back in to the hood. The cable assembly can be used to connect to the cable mount.

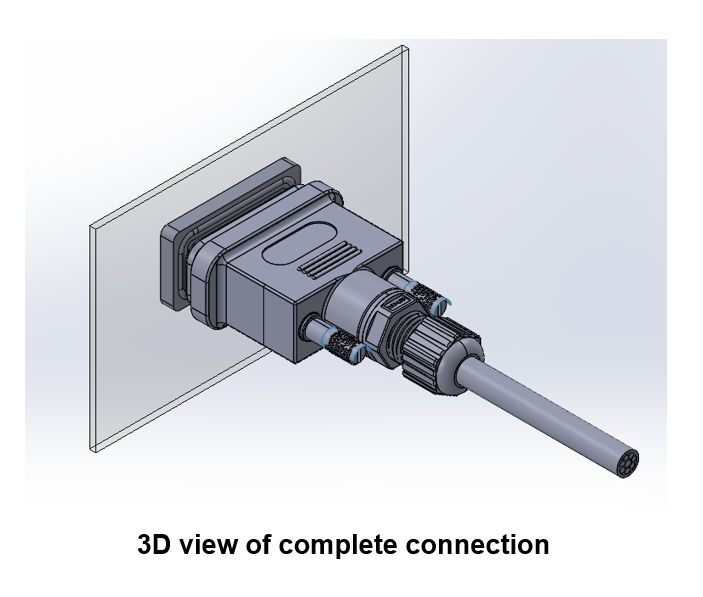

A combination of cable mount to panel mount (straight or right-angle) are always preferred. The blank on the panel allows the screws to mount the waterproof D-sub on the panel as well as the waterproof cable to connect to the D-sub. The rubber seal on the waterproof D-sub prevents water leakage from the blanks on the panel. After connecting the waterproof cable or over molded cable to the D-sub by thumb screws on the hood, the rubber seal on the cable can prevent water leaking into the connector and protect the contacts.

We continually update and advance our products to ensure that our customers have access to the latest and best products available. Contact us for additional information.