Spring Loaded Connectors

Categories

- Card Edge Connectors

- RECTANGULAR CONNECTORS

- D-Sub Connectors

- Machined D-Sub Connectors

- Power Combo D-Sub Connectors

- Parallel Port D-Sub Connectors

- Waterproof D-Sub Connectors

- DB9 Connector

- DB15 Connector

- DB25 Connector

- Vertical PCB D-Sub Connector

- D-Sub Panel Cut-outs

- Cable Wire D-Sub Connector

- PCB D-Sub Connector

- Right-angle PCB D-Sub Connector

- Backshells or Hoods, and Caps for D-Sub Connectors

- D-Sub Connector Housings

- D-Sub Connector Contacts

- Modular & Magnetic Jacks

- USB Connectors

- HDMI Connectors

- INLINE CONNECTORS

- HEADER CONNECTORS

- Spring Loaded Connectors

- Waterproof Connectors

- Cable Assemblies

- Custom Connectors

Search Parts:

Features & Benefits

- Magnets increase the reliability of the connection and provide polarization

- Spring-loaded contacts maintain connection in environments with vibration to provide stable current flow

- Precision machined to ensure high quality, low resistance, compliant connector giving it the edge over other technologies

- A reliable, precision-made interconnect solution ideal for a number of demanding application requirements in the fast-moving world of electronic interconnects

- Convenient for consumer electronics and in test environments where a large number of mating cycles are required (Up to 30,000 mating cycles)

- Assembled into high-temperature thermoplastic to form connector arrays

- High-quality “tear away” design prevents damage caused by unintended disconnection

- Magnets pull the connectors together and the user can pull them apart resulting in a quick mating and un-mating process

- More convenient than standard pogo connectors

Spring Loaded Connectors

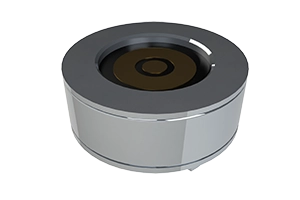

Magnetic Spring Loaded Connectors

Series |

Description |

|---|---|

685 Series

|

Magnetic Spring Loaded (Pogo Pin) Connectors | Male |

686 Series

|

Magnetic Spring Loaded (Pogo Pin) Connectors | Female |

MPF Series

|

Magnetic Spring Loaded (Pogo Pin) Connectors | Female | Circular and Rectangular |

MPM Series

|

Magnetic Spring Loaded (Pogo Pin) Connectors | Male | Circular and Rectangular |

Magnetic Spring Loaded Connector Cable Assemblies

Series |

Description |

|---|---|

687 Series

|

Magnetic Spring Loaded (Pogo Pin) Connector Cable Assemblies | Male |

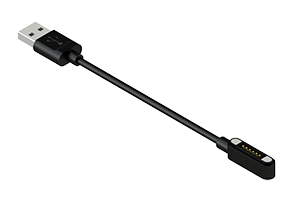

MCM Series

|

Magnetic Spring Loaded (Pogo Pin to USB A 2.0) Cable Assemblies | Male |

Magnetic Spring Loaded Connector Kit

Series |

Description |

|---|---|

689 Series

|

Magnetic Spring Loaded (Pogo Pin) Connector Kit |

What is a spring loaded or Pogo Pin connector?

Spring loaded ( pogo pin) connectors

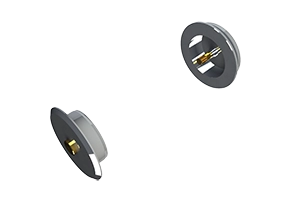

A Spring-Loaded Connector is a connector housing spring-loaded contacts or terminals. The terminals, primarily made of a barrel, spring, and plunger, have the same power and data-transmitting functionalities but differ in mating requirements. Whereas a common terminal would require a secure connection to ensure the contacts are mating, the spring-loaded terminals allow for a more flexible mating position.

Stroke Distance

What allows the flexible mating position is the stroke distance of the spring-loaded pins otherwise commonly known in the market as pogo pins. This stroke distance also helps in preventing minor misalignments that would break the connection when using a standard contact or terminal. The same stroke mechanism allows these connectors to be extremely reliable and durable in applications where mechanical shock or vibration is present.

The mating end could either be a pad connector, a flat-surfaced contact, or built directly into the printed circuit board (PCB).

As noted above, the spring-loaded pins are primarily made of a barrel, spring, and plunger. A ball or shell could be added inside the spring-loaded pin to increase durability and connectivity by increasing the contact points internally and allowing the pin to withstand a higher current.

Spring Loaded Pin or Pogo Pin Considerations

Spring-loaded pin considerations include the material used, the spring force of the spring, and the number of contact points. The material used will determine the conductivity of the pin while the roughness of the material could help increase the flow of current. The appropriate spring force helps press the plunger to the barrel ultimately stabilizing the stroke distance and current flow. Increasing the number of contact points through the use of a ball or shell provides additional stability in the current flow.

Magnetic Spring Loaded (Pogo Pin) Connectors

While the standard spring-loaded connectors are highly reliable, there are magnetic options available to further increase the reliability of the connection and allow blind mating. This means there is no mating hardware necessary as the magnet replaces the need for it. It also means that the spring-loaded connector self-aligns by locating the mating connector through the use of a magnet requiring zero force, unlike alternate connectors that require insertion and withdrawal forces to connect and disconnect, respectively.

The ability to be designed into very small footprints compliments the trend of smaller electronic products. Common applications for spring-loaded pins or connectors include medical, mobile, or telecommunication, audio or video, consumer, testing equipment, and any other application requiring or benefiting from connections being made quickly and easily.

Spring-loaded pin or pogo pin terminations:

- Through Hole

- Floating or Double-Ended

- SMT

- Screw

- Pressfit

We continually update and advance our products to ensure that our customers have access to the latest and best products available. Contact us for additional information.