Rectangular Connector Housing

- Rack and Panel Connectors

- Edacon Hermaphroditic Contact Design

- Hoods, back shells, and covers

- Rectangular Connector Housing

Categories

- Card Edge Connectors

- RECTANGULAR CONNECTORS

- D-Sub Connectors

- Machined D-Sub Connectors

- Power Combo D-Sub Connectors

- Parallel Port D-Sub Connectors

- Waterproof D-Sub Connectors

- DB9 Connector

- DB15 Connector

- DB25 Connector

- Vertical PCB D-Sub Connector

- D-Sub Panel Cut-outs

- Cable Wire D-Sub Connector

- PCB D-Sub Connector

- Right-angle PCB D-Sub Connector

- Backshells or Hoods, and Caps for D-Sub Connectors

- D-Sub Connector Housings

- D-Sub Connector Contacts

- Modular & Magnetic Jacks

- USB Connectors

- HDMI Connectors

- INLINE CONNECTORS

- HEADER CONNECTORS

- Spring Loaded Connectors

- Waterproof Connectors

- Cable Assemblies

- Custom Connectors

Search Parts:

What is a rectangular connector housing?

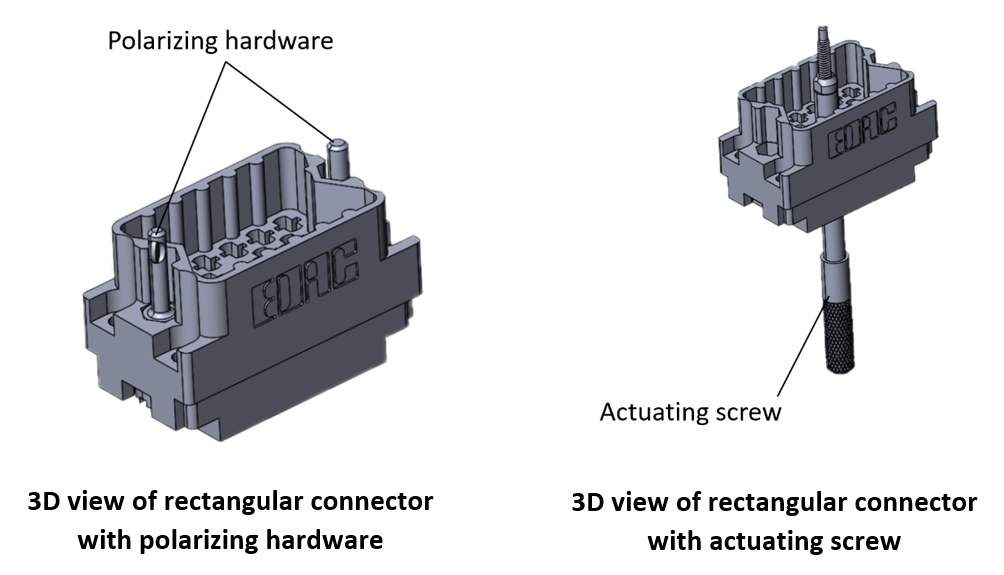

A rectangular connector housing is a shell made of thermoplastic without contacts. The insulator design prevents improper mating of individual plug and receptacle, and polarizing hardware enables specific plug and receptacle combinations. Both actuating screw and polarizing hardware are available. The plug/receptacle rectangular connector can be connected to each other by the hermaphroditic contact. The 516 series offers 20, 38, 56, 90 and 120, and 14 and 36 positions for the 519 series.

Insertion and Ejection Tools for EDAC rectangular connectors

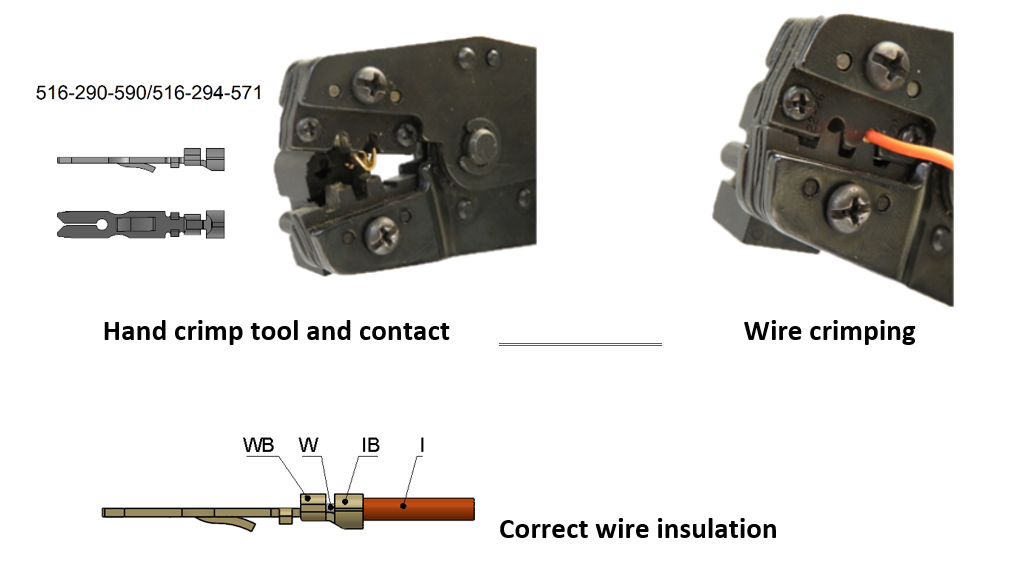

Hand crimp tool 516-280-201 is available to crimp the contacts 516-290-590/516-294-571 for EDAC rectangular connectors. Firstly, open the hand crimper and place the contact into the locator slot. Then, partially close the crimper until the contact is held in place. Insert the wire into the contact and close the crimper until the ratchet releases. Make sure the wire insulation (I) is properly located on the insulation barrel (IB) of the contact and wire copper (W) on the wire barrel (WB) of the contact.

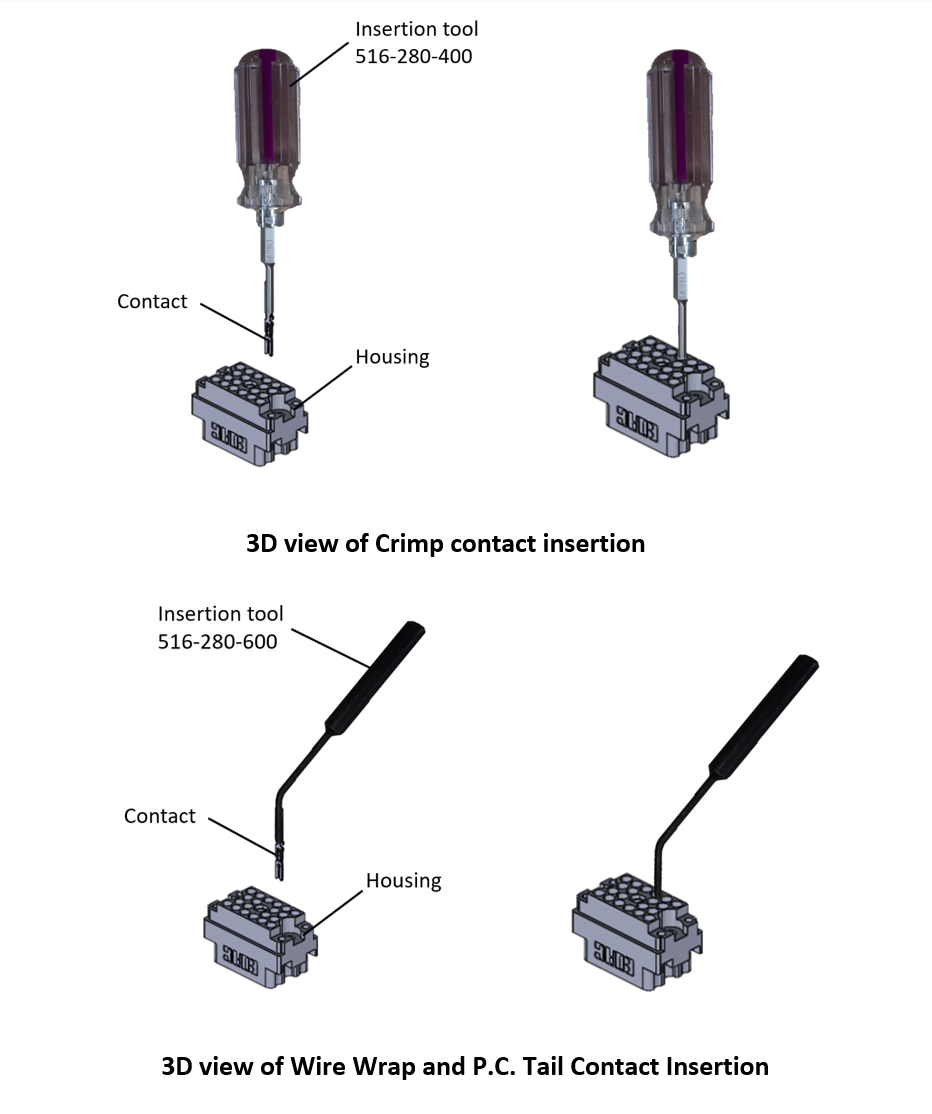

There are insertion tools for different contact options. The wire groove of the Crimp Contact Insertion Tool 516-280-400 locates the tool onto the end of the crimp form, while the slender tube of the Wire Wrap and P.C. Tail Contact Insertion Tool 516-280-600 protects the contact tail during insertion without interfering with adjacent contacts. Both tools insert the contact from the bottom of the rectangular housing. A successful insertion would produce a ‘click’ sound between the contact and housing.

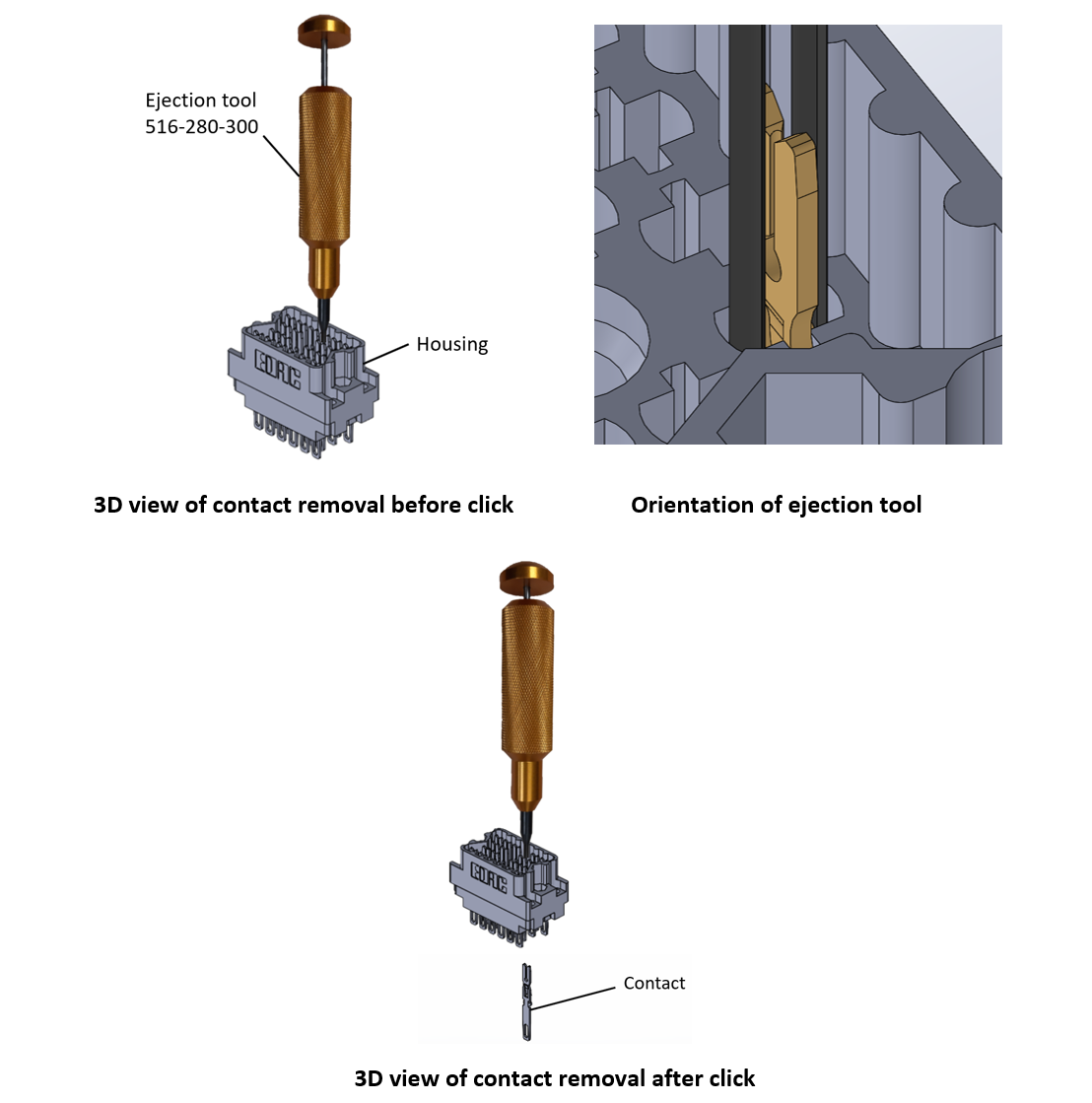

When it comes to contact removal, the contact ejection tool, 516-280-300, provides easy positive ejection, without damage to the insulator, with one press. The tip of the ejection tool should be inserted as deep as possible into the hole of the housing from the top in the correct orientation, seen below. Then, the tip can push the contact away from the slot of the housing. After pressing the end of the ejection tool, the ejecting pin will push the contact through the tip and remove the contact.

We continually update and advance our products to ensure that our customers have access to the latest and best products available. Contact us for additional information.