Wire Connectors

- Wire to Wire and Wire to Board Connectors

- Waterproof Wire to Wire and Wire to Board Connectors

- Wire Connectors

- Waterproof Wire Connectors

- Double Latch Technology

Categories

- Card Edge Connectors

- RECTANGULAR CONNECTORS

- D-Sub Connectors

- Machined D-Sub Connectors

- Power Combo D-Sub Connectors

- Parallel Port D-Sub Connectors

- Waterproof D-Sub Connectors

- DB9 Connector

- DB15 Connector

- DB25 Connector

- Vertical PCB D-Sub Connector

- D-Sub Panel Cut-outs

- Cable Wire D-Sub Connector

- PCB D-Sub Connector

- Right-angle PCB D-Sub Connector

- Backshells or Hoods, and Caps for D-Sub Connectors

- D-Sub Connector Housings

- D-Sub Connector Contacts

- Modular & Magnetic Jacks

- USB Connectors

- HDMI Connectors

- INLINE CONNECTORS

- HEADER CONNECTORS

- Spring Loaded Connectors

- Waterproof Connectors

- Cable Assemblies

- Custom Connectors

Search Parts:

wire connector

Wire connectors are used to make a wire to wire or wire to board connection.

Engineering options

There are many types of wire connectors including D-sub connectors, IDC connectors, spade terminals, ring terminals & custom contacts.

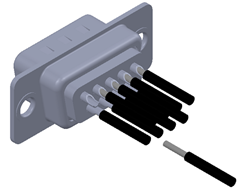

D-sub connectors with solder cup contacts have a cavity into which the stripped and tinned wire is inserted and then soldered. The picture below shows a D-sub connector (plug or socket) with solder cup contacts.

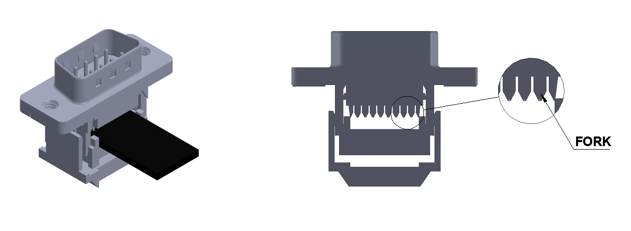

I.D.C. (Insulation Displacement Contact) connectors are designed to be connected to the conductor(s) of a flat cable. The flat cable is pressed against the contacts, the rear of which is fork-shaped, which then pierce the insulation of all the wires simultaneously. The picture below shows an I.D.C. D-sub male connector. Various I.D.C. connector types are available (ex. Dip connector, D-sub, socket header).

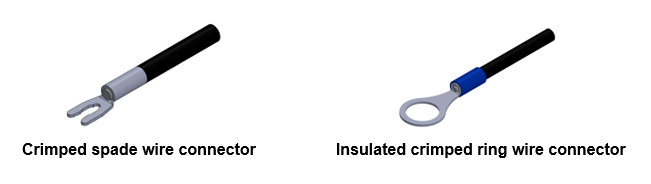

Crimp-on wire connectors are generally made of steel or copper. Crimp-on wire connectors require a crimping tool designed specifically for the contact. They are permanent (not reusable) and designed for making pressure-type connections. Crimp-on connectors provide a very secure connection. They can be used with or without plastic insulations.

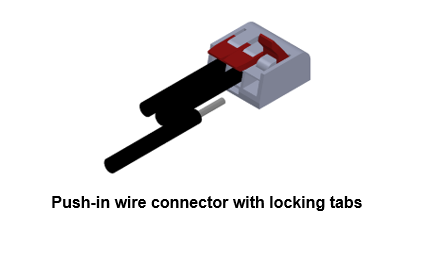

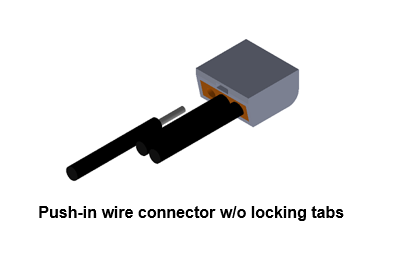

Push-in

connectors are designed with or without locking tabs. Push-in connectors with

locking tabs provide the ability to remove previously inserted wires.

We continually update and advance our products to ensure that our customers have access to the latest and best products available. Contact us for additional information.