Products

- Card Edge Connectors

- RECTANGULAR CONNECTORS

- D-Sub Connectors

- Machined D-Sub Connectors

- Power Combo D-Sub Connectors

- Parallel Port D-Sub Connectors

- Waterproof D-Sub Connectors

- DB9 Connector

- DB15 Connector

- DB25 Connector

- Vertical PCB D-Sub Connector

- D-Sub Panel Cut-outs

- Cable Wire D-Sub Connector

- PCB D-Sub Connector

- Right-angle PCB D-Sub Connector

- Backshells or Hoods, and Caps for D-Sub Connectors

- D-Sub Connector Housings

- D-Sub Connector Contacts

- Modular & Magnetic Jacks

- USB Connectors

- HDMI Connectors

- INLINE CONNECTORS

- HEADER CONNECTORS

- Spring Loaded Connectors

- Waterproof Connectors

- Cable Assemblies

- Custom Connectors

Success with University of Waterloo Formula Motorsports

Ranked among the top 50 Engineering schools worldwide and the largest in Canada, the University of Waterloo, established in 1957 has grown to be recognized as having an elite Engineering program and is committed to leading in education and research excellence.

The University of Waterloo Formula Motorsports team (UWFM) designs, builds and tests an open-wheel formula-style race car. They compete in the Formula SAE Series, which is the most internationally recognized Collegiate Design Series event hosted by the Society of Automotive Engineers (SAE). The Formula SAE Competition challenges students to design, fabricate, market, and race brand-new race cars every year across North America and Europe. This faculty volunteer program develops soft skills, critical thinking, fosters teamwork, and addresses the specific needs of the mobility industry today.

Six specialty systems have been created to address the needs of the open-wheel formula style race car which includes a team for aerodynamics, business, chassis or the frame, electronics, powertrain, and the suspension. Each of these systems will contribute to the success in both static and dynamic events in Formula SAE. The static event consists of an engineering design competition, marketing presentation, cost report, and technical inspection, whereas the dynamic event includes acceleration, skid pad, autocross, and 22km endurance.

Partnership

EDAC, a connector manufacturer with nearly 60 years of interconnect engineering design experience, has become a sponsor of the formula motorsports team at the University of Waterloo. EDAC helped solve a problem with the electronic system team on sensor continuity. As this is vital for collecting data and adjusting the race car for performance. We are proud of the effort and success the team has had in the 2022 racing season, recently placing 13th overall at the Michigan Formula SAE race, and look forward to contributing further to the 2023 season onward.

Understanding the application

An open-wheel race car comes with many environmental challenges, mainly but not limited to, high vibration, shock, and water exposure. The free-hanging application of the required connectors, and placement close to the race car’s engine, brings retention and operating temperature into consideration as well.

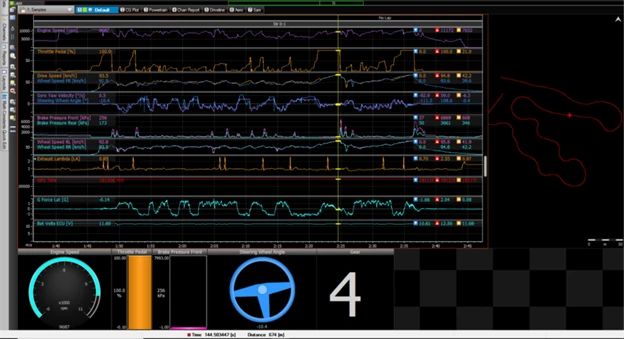

Finding the right connector is important to the application as Formula SAE allows live telemetry and the team logs that data to pull it offline after the car has run. The connector will be responsible for sensors to pull data to measure performance numbers to have a more controlled and data-driven tuning.

Understanding the need

The requested connector would need to provide 5V of power and transmit data for sensors placed throughout the race car and must withstand the harsh environment while racing.

Data collection during competitions will affect the performance of the race car, this means a highly reliable connector must be chosen. Some common data being collected from sensors by race teams include:

- Laser ride height sensor: This sensor measures the distance from the sensor (and therefore the underside of the chassis) to the ground. This data is particularly useful on high downforce cars to make sure the car is operating within a preferred ride height window; tire compression can be considered which is not possible with damper potentiometers alone.

- Hall-effect sensor: Primarily rotational speeds such as wheel speeds, crankshaft, and camshaft speeds/position. Wheel speeds can be used to analyze vehicle/driver performance, who went faster, which setup was faster etc. Cam/Crank sensors work together to tell the ECU when to trigger injectors, engine RPM, and rev limit.

- Steering (rotary) potentiometer: Used for performance analysis, can show understeer, and oversteer, whether it is chassis or driver induced. Comparing two drivers can aid in driving style improvements.

- Damper (linear) potentiometer: Shows range of wheel movement and rate of wheel movement, used for chassis setup

- Global Position System (GPS): Most helpful for tracing driving lines, improved car position on track can lead to improved lap times, also helpful as a vehicle speed back up.

- Lap beacon sensor: Trigger for lap time recording

- Pressure sensor (e.g., brakes): Again, useful for driver analysis, the maximum brake pressure applied, braking points, and braking duration. Engine pressures such as air intake, are useful for engine tuning, and oil; is more of a safety aspect.

- Temperature sensor: Primarily for engine parameter monitoring, often used to monitor brake temps and sometimes tire surface temps. Brakes have a preferred operating window, as do tires.

- Lambda sensor: Measures the amount of unburnt oxygen present in the exhaust pipe. The output of this sensor is used to adjust the air/fuel mixture in the engine to ensure optimal power output is achieved.

- Gyroscopic sensor: used to measure rotational acceleration, for example, rotational acceleration around the Z axis can be used to show a rate of change of direction.

Each sensor above feeds data to the data logger where data is then extracted by the race team for analysis. Some will feed the engine ECU to ensure operation within the set safety parameters.

The importance of the continuity of a connector, especially on a chassis experiencing high vibration, is paramount as a malfunction could lead to data loss that may impede on the teams’ ability to improve on-track performance. To further illustrate the importance, see the following examples where data loss would directly impact the team’s on-track performance.

- Chassis sensors are put in place to monitor the driver’s inputs and the race car’s reaction to those inputs. Often changing the chassis setup will help the driver put in a faster lap time, and occasionally changing the way the driver executes will produce a faster lap time, both of which are made possible by collecting and analyzing data.

- Engine sensors are there to aid in the tuning of the engine to get the best performance and during a race weekend, when the tuning is complete, monitoring the engine and making sure everything is within the desired operating window. Should the continuity of a drive-train sensor connector be lost, the engine and/or transmission could be damaged, potentially ending the race.

Choosing the correct connector for the application

Through collaboration, EDAC engineering and engineering students from the University of Waterloo agreed that the 560 Inline Waterproof series connectors, with double-latch technology, would be able to address the necessary requirements and be rugged enough to withstand the harsh racing environment.

The 560 series connectors have an operating temperature range of -40°C to +105°C and an Ingress Protection rating of IP67. The operating temperature max of 105°C helps the connector endure higher temperatures found around the race car’s engine while the IP67 grade provides absolute protection from dust and water exposure on the racetrack.

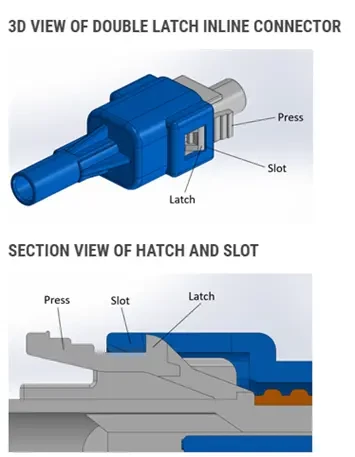

The double-latch technology provides better vibration resistance and increased retention, 20% more retention than a single-latch alternative. The increased vibration resistance and retention help maintain the connection for power and data transmission during races.

During the connection, the plastic latches on the top and bottom of the receptacle connector will slide into the housing until they reach the slots. The slots lock them in place between the male and female inline connectors. This offers a ruggedized connector suitable for harsh environments and ensures a closed connection between 2 connectors while free hanging within the chassis of the formula racing car.

The required connector is going to be placed near the engine and is free hanging, so establishing a strong vibration resistance and retention strength would be ideal for this application. For this, we put the connector through a series of tests for vibration retention and shock.

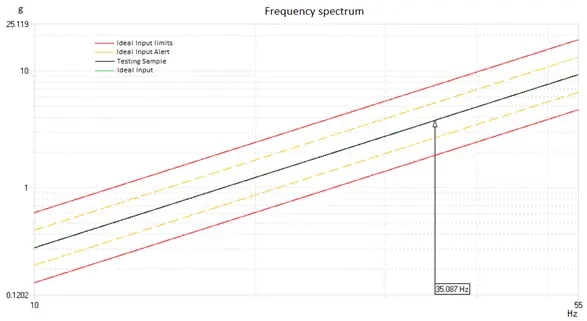

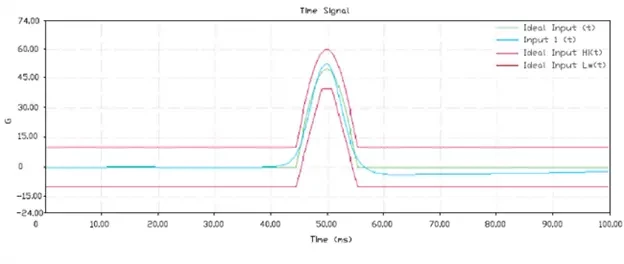

For vibration testing, in accordance with MIL-STD-202G 201, the 560 series inline waterproof connectors were attached to 3 axes for 2 hours on each axis at 10Hz-55Hz-10Hz with a maximum amplitude of 1.52mm. During the test, the connector did not appear more than 1ms interrupt phenomenon and the low-level contact resistance was around 5mΩ to 7mΩ and was below and equal to 8mΩ after the test. During the test, the sample did not fall off, rupture, or damage, and the connector joint did not separate.

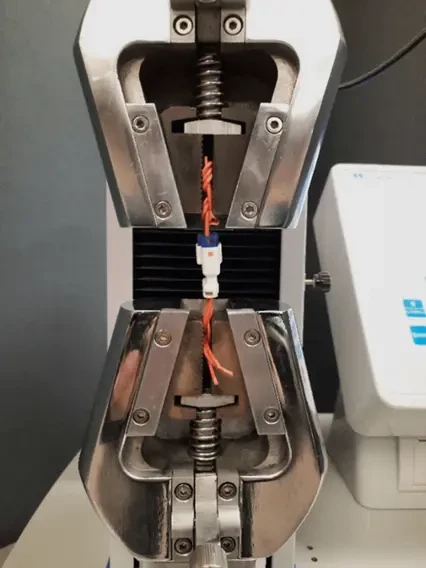

The retention force test was conducted to test the retention force between the male and female double latch inline connectors versus single latch male and female connectors. The connectors were clamped on the Tensile Testing machine with no external force being introduced before the testing. It was then pulled at the rate of 25mm/min speed. The end results with the double latch connector retention force averages around 10kgf, and the single latch averaging around 8kgf. Results showed a 20% resistance increase in the double latch connector.

The double latch technology has been shown to contain 20% more retention than single latch connectors. During the connection, the plastic latches on the top and bottom of the receptacle connector will slide into the housing until they reach the slots. The slots lock them in place between the male and female inline connectors. This offers a ruggedized connector suitable for harsh environments and ensures a closed connection between 2 connectors while free hanging within the chassis of the formula racing car.

"This year has

been one of our most reliable cars overall - especially electronically; there's

no doubt EDAC contributed to that success." - Nirosh Ratnarajah,

Electronics Lead of Waterloo Formula Motorsports

The formula motorsports team, specifically the electronics systems team, saw a measurable improvement with the distance life cycle increasing year over year after switching to the EDAC Waterproof Inline Connector. EDAC is looking forward to a continued partnership with the University of Waterloo’s formula motorsport team, and to continue being an engineering resource when needed for any interconnect solutions required.

We continually update and advance our products to ensure that our customers have access to the latest and best products available. Contact us for additional information.

Additional Resources:

EDAC's Resource Center (Environmental Compliance Statements Available)

Go Back