Search Parts:

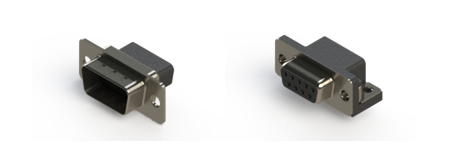

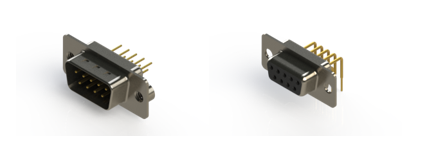

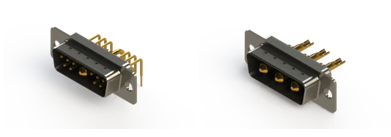

D-Sub+ D-shaped connectors

In the D-Sub+ family, EDAC offers an extensive range of industry standard D-Subminiature connectors. Available in standard density with 9, 15, 25, 37, and 50 contacts or high-density versions with 15, 26, 44, 62 and 78 contacts. Vertical and right-angle orientations, along with a variety of termination, plating and mounting options are available. They’re also available in a stacked version.